Ojiji nke aluminom extrusion n'ichepụta ngwaahịa na nrụpụta abawanyela nke ukwuu n'ime iri afọ ndị na-adịbeghị anya.

Dị ka akụkọ na-adịbeghị anya sitere naTeknavio, n'etiti 2019-2023 uto nke aluminom zuru ụwa ọnụ ahịa extrusion ga-eji a Compound Annual Growth Rate (CAGR) nke fọrọ nke nta 4%.

Ikekwe ị nụla usoro nrụpụta a ma na-eche ihe ọ bụ na otu o si arụ ọrụ.

Gịnị bụ aluminom extrusion?

Aluminom extrusion bụ usoro nke aluminom alloy ihe na-amanye site a anwụ na a kpọmkwem cross-section profaịlụ.

Aluminom extrusion nwere ike iji tụnyere squeezing ntacha eze site na tube.A dị ike ebulu na-akpali aluminum site na anwụ na ọ pụta ìhè na-anwụ oghere. table.N'ogo dị mkpa, usoro nke aluminom extrusion dị mfe nghọta.

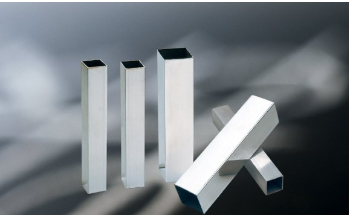

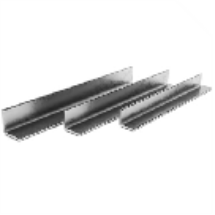

N'elu bụ eserese ndị a na-eji emepụta anwụ na n'okpuru ebe a bụ nsụgharị nke ihe profaịlụ aluminom emechara ga-adị ka.

Ụdị ndị anyị na-ahụ n'elu dị nnọọ mfe, ma usoro extrusion na-enyekwa ohere ịmepụta ụdị nke dị mgbagwoju anya karị.

OleUsoro?

Ka anyị leba anya n'okpuru Aluminom Art.Ọ bụghị naanị na a mara mma eserese, nke na-agụnye ọtụtụ nzọụkwụ nke aluminum extrusion.

1):A na-akwado Extrusion Die ma bugharịa ya na Extrusion Press

Nke mbụ, a na-eji ígwè H13 eme ihe anwụ dị okirikiri.Ma ọ bụ, ọ bụrụ na ọ dịlarị, a na-adọpụta ya n'ụlọ nkwakọba ihe dịka nke ị na-ahụ ebe a.

Tupu ịpụ apụ, a ga-ekpochasị ọnwụ ahụ n'etiti 450-500 degrees celsius iji nyere aka mee ka ndụ ya dịkwuo elu ma hụ na ọbụna ígwè na-asọpụta.

Ozugbo anwụ na-ekpo ọkụ, enwere ike ibunye ya n'ime ihe ntanetị extrusion.

2):Aluminom Billet na-ekpo ọkụ tupu ewepu ya

Na-esote, a na-ebipụ ihe mgbochi siri ike, cylindrical nke aluminom alloy, nke a na-akpọ billet, site na ndekọ ogologo oge nke ihe alloy.

A na-ekpocha ya na oven, dị ka nke a, n'etiti 400-500 Celsius.

Nke a na-eme ka ọ bụrụ ihe na-adịghị mma maka usoro extrusion ma ọ bụghị nke gbazere.

3) A na-ebufe Billet ahụ na Extrusion Press

Ozugbo billet agbachagoro ọkụ, a na-ebufe ya n'ụzọ igwe na igwe nrụnye.

Tupu etinye ya n'akwụkwọ akụkọ, a na-etinye mmanụ mmanu (ma ọ bụ ihe ntọhapụ) na ya.

A na-etinyekwa ihe ntọhapụ ahụ na ebule extrusion, iji gbochie billet na ebule ịrapara ọnụ.

4)Ram na-agbanye ihe Billet n'ime akpa ahụ

Ugbu a, a na-ebunye billet ahụ na-adịghị ahụkebe n'ime igwe mgbasa ozi extrusion, ebe ebule hydraulic na-etinye ihe ruru tọn 15,000 nke nrụgide na ya.

Ka ebule ahụ na-etinye nrụgide, a na-atụba ihe billet ahụ n'ime akpa nke ịpịpụta extrusion.

Ihe na-agbasawanye iji mejupụta mgbidi nke akpa ahụ

5)Ihe Extruded Ihe Na-apụta Site na Die

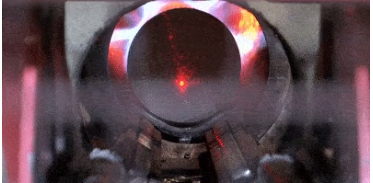

Dị ka ihe alloy na-ejupụta akpa ahụ, a na-agbanye ya ugbu a megide extrusion anwụ.

Site na nrụgide na-aga n'ihu na-etinye ya na ya, ihe aluminom enweghị ebe ọ ga-aga ma e wezụga site na oghere (s) na anwụ.

Ọ na-apụta site na oghere anwụ anwụ na ọdịdị nke profaịlụ zuru oke.

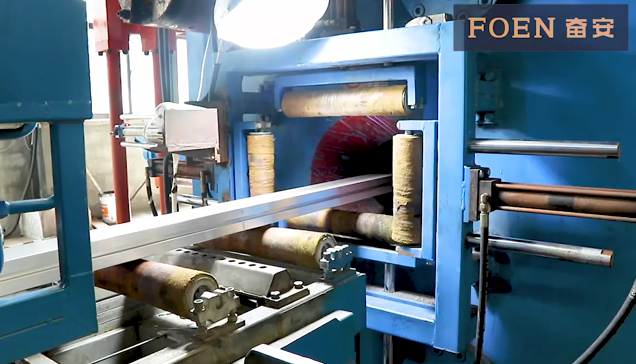

6)A na-eduzi extrusions n'akụkụ Tebụl Runout na emenyụ

Mgbe ọ pụtachara, a na-ejide extrusion ahụ site na onye na-adọkpụ, dị ka nke ị na-ahụ ebe a, nke na-eduzi ya n'akụkụ tebụl runout na ọsọ ọsọ nke dabara na ọpụpụ ya site na pịa. ” ma ọ bụ n'otu n'otu na-ajụ oyi site na ịsa mmiri ma ọ bụ ndị fan n'elu tebụl.

7)A na-akpacha ihe mkpofu ruo ogologo tebụl

Ozugbo extrusion ruru ogologo tebụl ya zuru oke, a na-akpụ ya site na nkwọ ọkụ iji kewapụ ya na usoro extrusion.

Na usoro ọ bụla nke usoro ahụ, okpomọkụ na-arụ ọrụ dị mkpa.

N'agbanyeghị na extrusion a kwụsịrị mgbe ọ pụtachara n'akwụkwọ akụkọ, ọ kachabeghị nke ọma.

8)A na-ajụkwa mpụpụ ka ọ bụrụ okpomọkụ ụlọ

Mgbe a na-akpacha osisi, a na-ebugharị extrusions ogologo okpokoro site na tebụl runout gaa na tebụl dị jụụ, dị ka nke ị na-ahụ ebe a. Profaịlụ ga-anọgide n'ebe ahụ ruo mgbe ha ruru okpomọkụ.

Ozugbo ha mechara, ọ ga-adị mkpa ka a gbatịa ha.

A na-ajụkwa mpụpụ ka ọ bụrụ okpomọkụ ụlọ

Mgbe a na-akpachasị ihe, a na-eji ígwè arụ ọrụ ebufe extrusions dị ogologo tebulu site na tebụl runout gaa na tebụl jụrụ oyi, dị ka nke ị na-ahụ ebe a.

Profaịlụ ga-anọ ebe ahụ ruo mgbe ha ruru okpomọkụ ụlọ.

Ozugbo ha mechara, ọ ga-adị mkpa ka a gbatịa ha.

9)A na-ebuga mgbatị ahụ na Stretcher ma gbatịa n'ime Nhazi

Ụfọdụ ihe ntụgharị eke emewo na profaịlụ na nke a kwesịrị imezi ya. Iji dozie nke a, a na-akwaga ha na ebe a na-adọba ụgbọala. A na-ejide profaịlụ ọ bụla n'ụzọ na-arụ ọrụ na nsọtụ abụọ ahụ wee dọpụta ya ruo mgbe ọ zuru oke ma wetara ya nkọwapụta.

10)A na-ebuga npụpụ ahụ gaa n'ịhụchachaa ma bepụ ya n'ogologo

Site na extrusions ogologo okpokoro dị ugbu a kwụ ọtọ ma na-arụ ọrụ zuru oke, a na-ebufe ha na tebụl osisi.

N'ebe a, a na-akụ ha n'ogologo akọwapụtara nke ọma, n'ozuzu n'etiti 8 na 21 ụkwụ n'ogologo.N'ebe a, ihe onwunwe nke extrusions kwekọrọ na iwe.

Gịnị na-eme na-esote?

Ngwucha elu: Na-eme ka ọdịdị na nchedo corrosion dịkwuo elu

Isi ihe abụọ mere a ga-eji tụlee ihe ndị a bụ na ha nwere ike ime ka ọdịdị nke aluminom dịkwuo mma ma nwee ike ịkwalite ihe ndị na-emebi emebi.Ma enwerekwa uru ndị ọzọ.

Dịka ọmụmaatụ, usoro nke anodization na-eme ka oyi akwa oxide nke metal ahụ na-eme ka ọ dịkwuo mma, na-eme ka nkwụsị nke corrosion ya dịkwuo mma ma na-eme ka ígwè ahụ na-eguzogide ike iyi ya, na-eme ka ikuku dị elu, na-enye elu dị elu nke nwere ike ịnakwere agba agba dị iche iche.

Usoro mmecha ndị ọzọ dị ka eserese, mkpuchi ntụ ntụ, sandblasting, na sublimation (iji mepụta anya osisi), nwekwara ike ime ya.

Aluminom extrusion bụ usoro maka ịmepụta akụkụ nwere profaịlụ cross-section kpọmkwem site na ịkwanye ihe alloy na-ekpo ọkụ site na die. Ọ bụ usoro mmepụta ihe dị mkpa.

Oge nzipu: Mee-10-2021